Xycle Secures Funding for Innovative Plastic Recycling Plant in Rotterdam

Rotterdam, Monday, 10 March 2025.

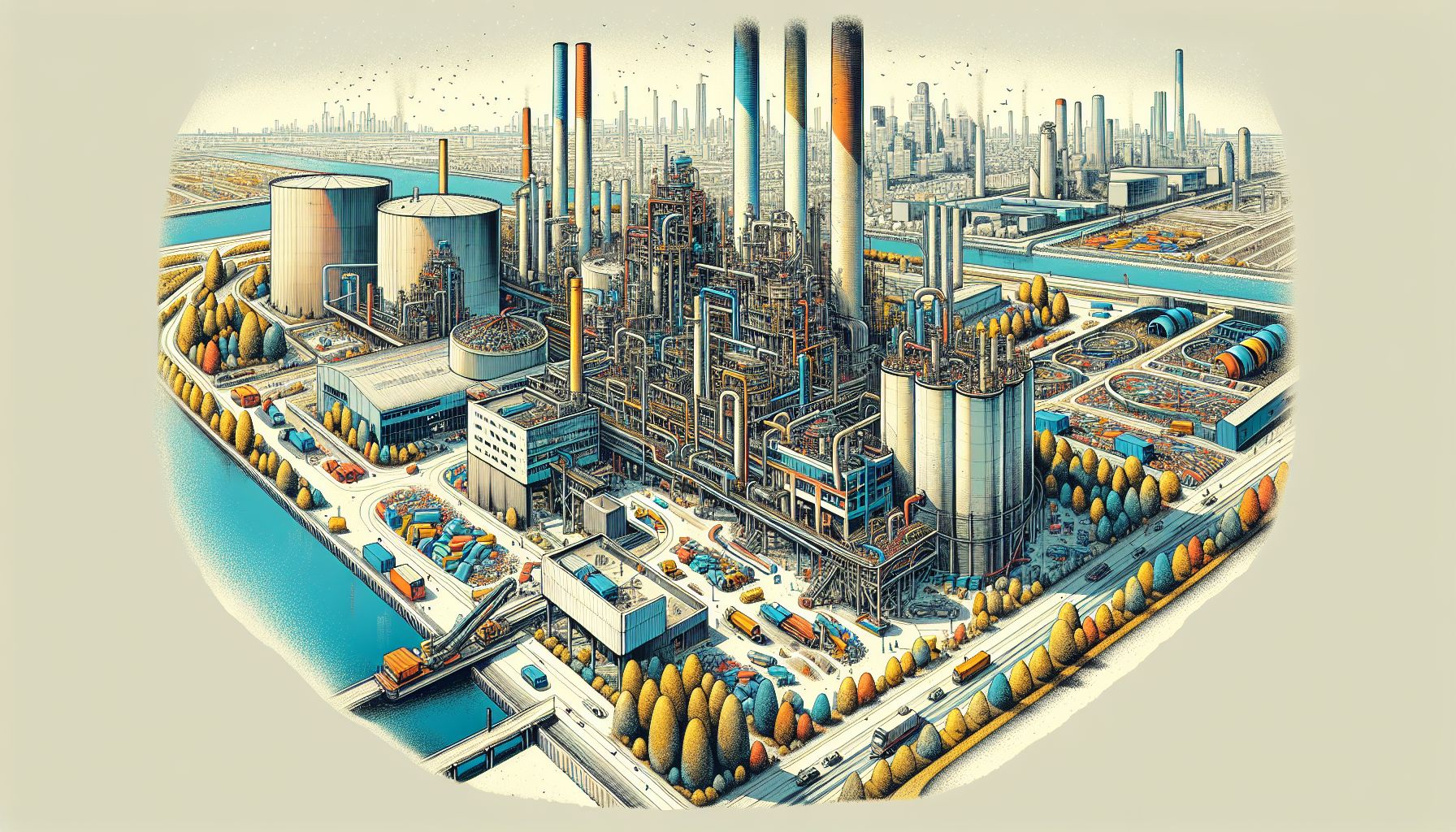

Xycle, a Rotterdam-based chemical recycling firm, has secured funding to build a plant capable of processing 21,000 tonnes of plastic waste annually, marking a pivotal step towards a circular plastic economy.

Strategic Investment and Technology

The funding announcement, made on March 8, 2025, brings together a powerful consortium of investors including Dow, ING, Invest-NL, Polestar Capital, and Vopak [1][2]. The facility, which began construction in November 2024, employs innovative low-temperature pyrolysis technology to convert difficult-to-recycle plastic waste into pyrolysis oil, which will be used as cracker feedstock for new plastic production [2][3]. This technological breakthrough comes at a crucial time, as global plastic production reached approximately 414 million tonnes in 2023, with only a 10% recycling rate [4].

Operational Scope and Impact

The plant, situated in Rotterdam’s Europoort, is designed with a modular layout that allows for flexible production scaling [1][2]. Dow, as a key investment partner, will serve as an off-taker for the circular feedstock, using it to manufacture virgin-quality circular plastics [2]. The facility’s annual processing capacity of 21,000 metric tons represents a significant step toward meeting the European Union’s ambitious recycling targets [1][2].

Future Expansion Plans

With the Rotterdam facility scheduled to begin operations in Q4 2026 [1], Xycle is already planning global expansion. The company aims to develop additional chemical recycling facilities worldwide, with plans to increase single plant capacity to 100,000 metric tons annually through larger reactor sizes [1]. This expansion aligns with Xycle’s testing facility in Moerdijk, Netherlands, which has already analyzed over 35 polymer waste streams, and feasible projects have been identified for Belgium, Denmark, and other locations in the Netherlands [3].