BMW's Robot Revolution: Figure 02 Achieves 400% Speed Boost in Sheet Metal Processing

Germany, Monday, 25 November 2024.

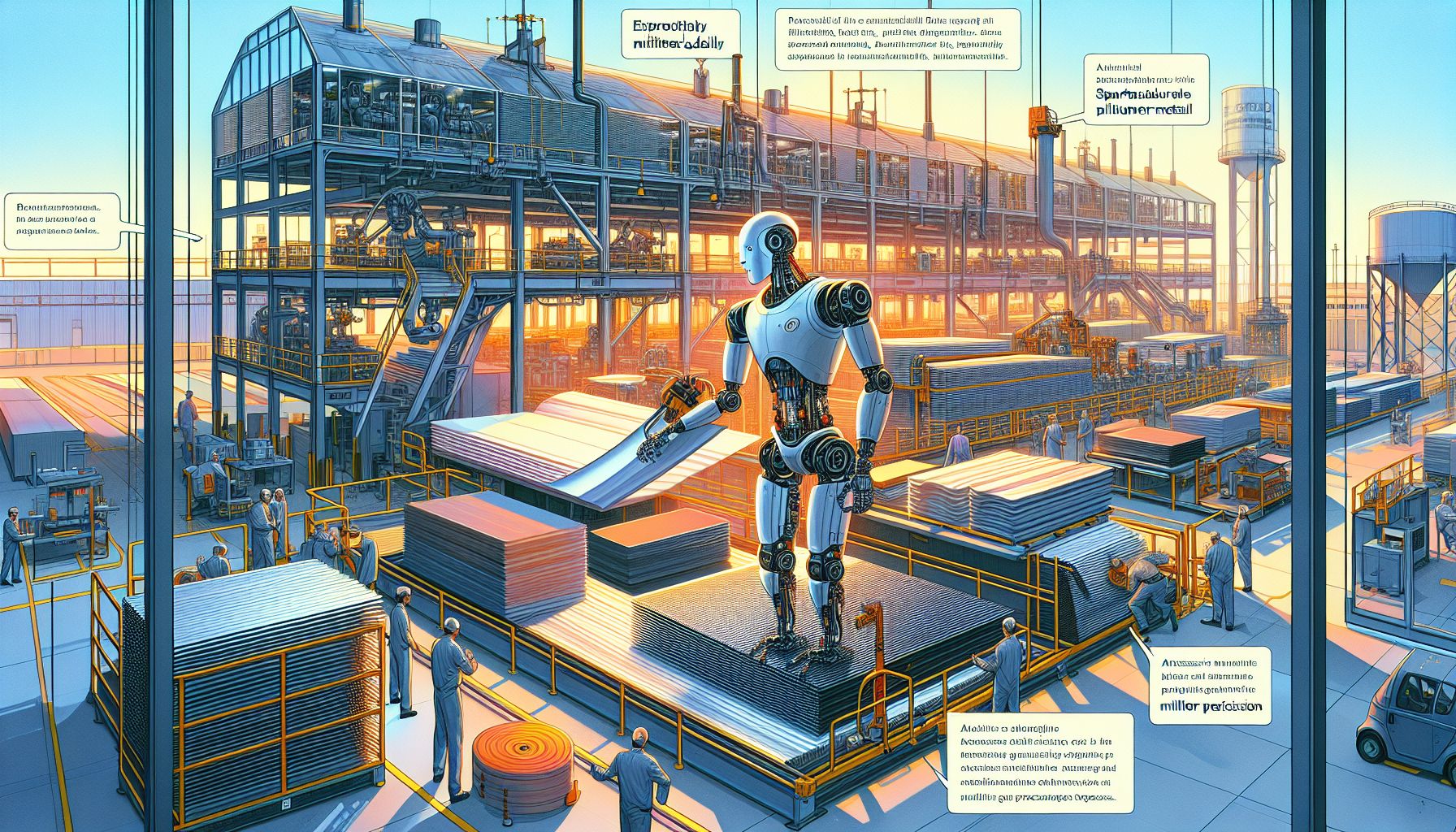

In a groundbreaking development at BMW’s Spartanburg plant, the humanoid robot Figure 02 has demonstrated unprecedented efficiency gains, processing 1,000 metal sheets daily with millimeter precision. This achievement marks a significant milestone in manufacturing automation, backed by a $675 million investment from tech giants including OpenAI and Microsoft. The robot is scheduled to resume operations in January 2025, promising even greater performance improvements as its AI models evolve through increased data collection.

The Innovation Behind Figure 02

The Figure 02 robot, developed by Figure AI, represents a significant technological leap in the field of humanoid robotics, specifically designed for industrial applications. Equipped with human-scale hands, six RGB cameras, and advanced AI perception models, Figure 02 is capable of executing high-precision pick-and-place tasks autonomously. This robot is a product of cutting-edge research and development, with its AI models trained using synthetic data generated in NVIDIA’s Isaac Sim environment, enabling it to perform tasks with remarkable speed and accuracy[1][4].

Impact on the Manufacturing Sector

The deployment of Figure 02 in BMW’s Spartanburg plant has revolutionized sheet metal processing by increasing efficiency by 400%. This advancement not only enhances production speed but also significantly improves the success rate of tasks requiring millimeter-level precision. The robot autonomously places 1,000 metal sheets daily, a task that is described as 10 times more challenging than typical stationary manipulation tasks[3]. Such improvements in robotic efficiencies are pivotal for BMW’s strategy to optimize production processes and maintain its competitive edge in the automotive industry[6].

Strategic Investments and Future Prospects

The success of the Figure 02 robot has attracted substantial investment from major tech companies, including OpenAI, Microsoft, and Nvidia. A Series B funding round raised $675 million, valuing Figure AI at approximately $2.6 billion[3]. This capital influx not only underscores the potential of humanoid robotics in manufacturing but also accelerates the deployment of more robots in real-world environments, as planned for 2025. Brett Adcock, CEO of Figure AI, has expressed confidence that the performance of Figure 02 will continue to improve with more data and AI model refinement[3].

Challenges and the Road Ahead

Despite these advancements, integrating humanoid robots like Figure 02 into manufacturing processes poses challenges, such as ensuring reliability and achieving a favorable return on investment. Currently, the operational cost of these robots is high, but as technology advances and costs decrease, the business case for widespread adoption will strengthen. BMW’s initiative is aligned with the principles of Industry 5.0, which emphasizes human-robot collaboration to enhance productivity while maintaining high-quality standards[6]. The anticipated return of Figure 02 in January 2025 is set to further showcase the potential of robotics in transforming manufacturing landscapes[3].