Dutch Recycling Facility to Transform 4,000 Tons of Plastic Annually

Delfzijl, Tuesday, 17 December 2024.

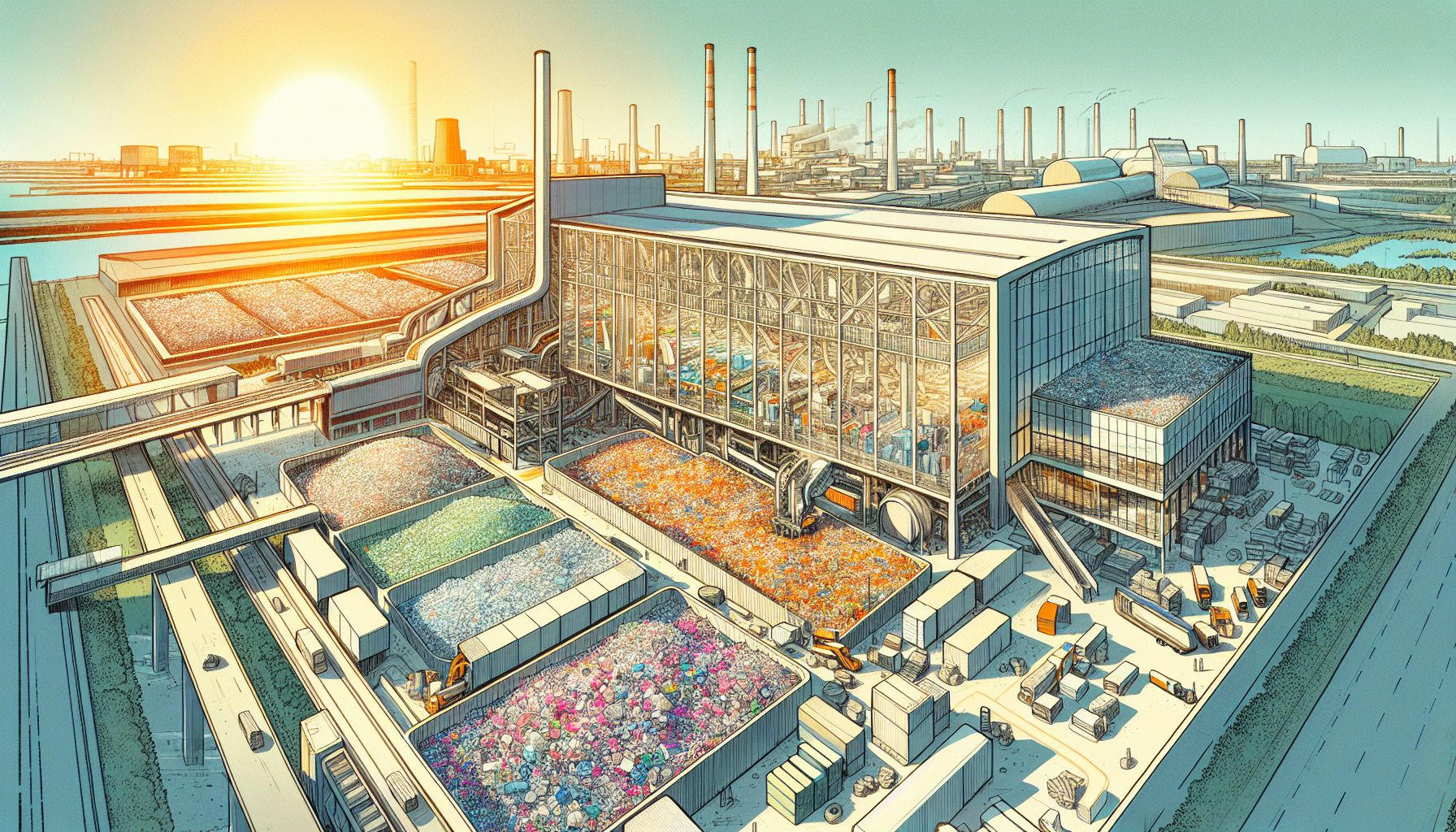

Uppact introduces a recycling facility in Delfzijl, Netherlands, to convert 4,000 tons of hard-to-recycle plastics into valuable materials, bolstering the circular economy.

Innovative Chemical Recycling Technology

The new facility, developed by Dutch scale-up Uppact, will employ advanced chemical recycling techniques through their proprietary Unwastor machine to process mixed and contaminated plastics [1]. This approach represents a significant advancement over traditional mechanical recycling, which faces limitations in processing contaminated or multi-layer plastics [2]. The facility’s location in Delfzijl strategically positions it to serve European markets while reducing dependency on overseas recycling operations [1].

Strategic Investment and Market Impact

The project has received crucial financial backing from sustainability-focused investors, including NOM (Investment and Development Agency for the Northern Netherlands) and Groeifonds [1]. This investment comes at a critical time, as the global market for post-consumer recycled plastics is experiencing significant growth, projected to reach US$26.8 billion by 2030 [5]. The facility’s annual processing capacity of 4,000 tons will contribute to meeting the growing demand for sustainable materials in Europe [1].

Environmental and Economic Benefits

This initiative aligns with the European Union’s push toward circular economy practices [3]. By processing materials locally, the facility will help reduce the environmental impact of plastic waste while creating valuable new materials for product designers, packaging designers, and interior designers [1]. The approach supports the EU’s broader goals of decreasing reliance on virgin raw materials and promoting sustainable consumption patterns [3].

Product Applications and Future Impact

The facility will produce recycled panels and boards suitable for outdoor furniture production, architectural applications, and infrastructure projects [1]. This development comes as regulatory initiatives and consumer awareness drive increased demand for sustainable materials [5]. The project exemplifies how local solutions can effectively address global challenges in plastic waste management while maintaining high-quality output standards [1][3].