Breakthrough: US Develops Recyclable Wind Turbine Blades

Netherlands, Saturday, 24 August 2024.

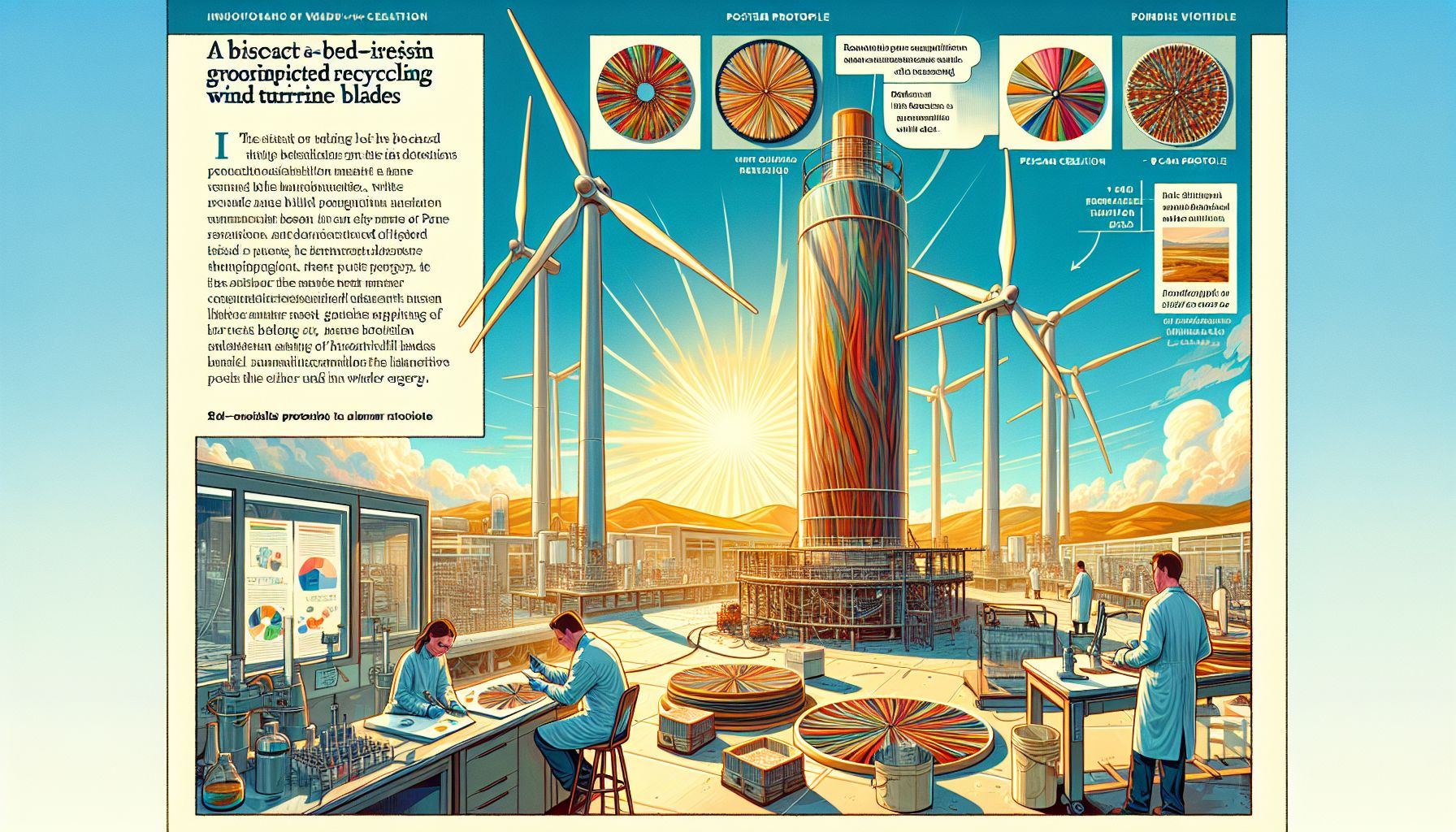

Researchers at the National Renewable Energy Laboratory have created a bio-based resin called PECAN for wind turbine blades. This innovation allows for chemical recycling of blades within six hours, potentially eliminating landfill waste and promoting a circular economy in wind energy. A 9-meter prototype demonstrates the resin’s viability for large-scale production.

A Sustainable Solution to a Growing Problem

The development of PECAN resin addresses a significant environmental challenge posed by the wind energy sector. As wind turbine blades reach the end of their 20-year lifespan, they often end up in landfills due to the non-recyclable materials traditionally used. The global waste from wind turbine blades is projected to exceed 43 million tons by 2050[1]. The PECAN resin, however, offers a sustainable alternative by enabling the chemical recycling of wind turbine blades, thus preventing the accumulation of waste in landfills.

The Science Behind PECAN Resin

PECAN, or PolyEster Covalently Adaptable Network, is derived from bio-based sugars. This innovative resin matches the performance of current industry-standard thermoset resins and even surpasses some recyclable thermoplastic resins[2]. The chemical recycling process for PECAN resin is remarkably efficient, capable of breaking down a blade within six hours. The components recovered from this process can be reused to manufacture new blades, highlighting the resin’s potential to foster a circular economy in wind energy materials.

Proving the Concept: The 9-Meter Prototype

To demonstrate the feasibility of PECAN resin, researchers at NREL constructed a 9-meter wind turbine blade prototype using vacuum-assisted resin-transfer molding. This prototype successfully showcased the manufacturing techniques required for larger blades, which can measure up to the length of a football field[3]. The prototype maintained its shape and withstood accelerated weathering tests, addressing concerns about ‘creep’ and deformation over time[3].

Industry Implications and Future Research

The successful development of PECAN resin has significant implications for the wind energy industry. By providing a viable recycling method, it could drastically reduce the environmental impact of wind turbine waste. The U.S. Department of Energy’s funding and support through its Advanced Materials and Manufacturing Technologies Office and Bioenergy Technologies Office have been crucial in this research[4]. Future research aims to explore larger blade manufacturing and additional bio-derived formulations, further advancing the sustainability of wind energy technology.

Expert Endorsements

Key figures in the research have expressed optimism about the potential of PECAN resin. Ryan Clarke, a postdoctoral researcher at NREL, emphasized the limitless approach of this technology if implemented correctly[4]. Johney Green, NREL’s associate laboratory director for Mechanical and Thermal Engineering Sciences, highlighted the critical step PECAN resin represents in fostering a circular economy for energy materials[1]. Nic Rorrer, a corresponding author, noted that the findings challenge the conventional belief that recyclable materials underperform in polymer science[2].