Dutch Innovation: Queen Máxima Inaugurates Bio-LNG Plant for Cleaner Shipping

Wilp, Saturday, 14 September 2024.

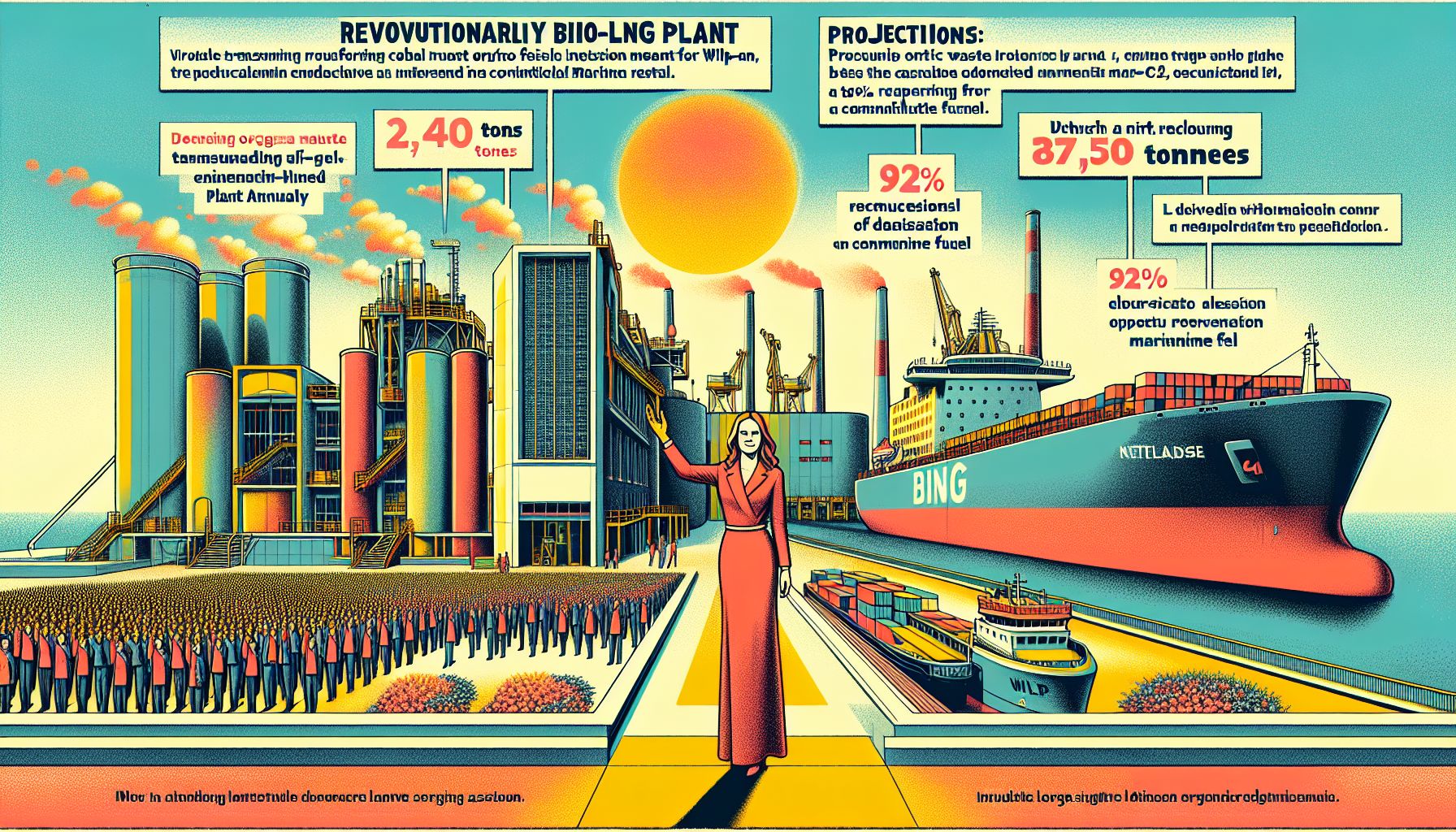

A groundbreaking bio-LNG plant in Wilp, Netherlands, transforms organic waste into sustainable fuel for maritime transport. The facility aims to produce 2,400 tons of bio-LNG annually, potentially reducing CO2 emissions by 87,500 tonnes over a decade and offering a 92% reduction in greenhouse gas emissions compared to conventional maritime fuel.

A Royal Inauguration

On Thursday, September 11, 2024, Her Majesty Queen Máxima officially inaugurated the new bio-LNG plant in Wilp, Gelderland. The event marked a significant milestone in the journey toward sustainable maritime transport. The plant, a collaborative effort between Dutch companies Attero and Nordsol, aims to convert biogas derived from vegetable, fruit, and garden waste (VGF) into high-purity bio-LNG, highlighting the potential of waste as a valuable resource for clean energy.

Innovative Technology and Environmental Benefits

The bio-LNG plant features state-of-the-art technology that transforms biogas from organic waste into renewable marine fuel. This innovative facility is expected to produce 2,400 tonnes of bio-LNG annually and 5,000 tonnes of liquid bio CO2. The transformation process significantly reduces greenhouse gas emissions, with bio-LNG offering a 92% reduction in emissions compared to conventional maritime fuels. Over the next decade, the plant is projected to reduce CO2 emissions by 87,500 tonnes, equivalent to the CO2 absorption of more than 4 million trees[1][2].

A Solution for Hard-to-Decarbonize Sectors

Bio-LNG is particularly valuable for sectors where full electrification remains unfeasible, such as long-haul transport, shipping, and aviation. The bio-LNG produced at the Wilp plant can be directly used in existing infrastructure, providing a scalable and cost-effective solution to reduce reliance on fossil fuels. The facility’s closed-loop system captures and recycles all gases emitted during production, ensuring minimal environmental impact[3][4].

European Support and Future Prospects

The European Union has recognized the potential of bio-LNG in achieving climate neutrality. The FirstBio2Shipping project received a €4.3 million grant from the EU, underlining its importance in the European Green Deal’s objectives. The European Parliament’s FuelEU Maritime Regulation aims to gradually reduce the greenhouse gas intensity of maritime fuels, with targets set to achieve an 80% reduction by 2050. The bio-LNG plant in Wilp aligns with these goals, paving the way for a sustainable future in maritime transport[5][6].

A Collaborative Effort for a Circular Economy

Attero and Nordsol’s joint venture demonstrates the power of collaboration in promoting a circular economy. By converting waste into valuable energy resources, the companies are not only cutting down on greenhouse gas emissions but also reducing reliance on imported fossil fuels. This project underscores the importance of local production of renewable fuels in advancing the sustainability of heavy transport. As noted by Léon van Bossum, CEO of Nordsol, the technology developed can be applied to many of Europe’s 20,000 biogas plants, further enhancing the continent’s energy independence[2][3].