GLS Netherlands Pioneers Robotic Parcel Sorting with ROSI

Utrecht, Tuesday, 15 October 2024.

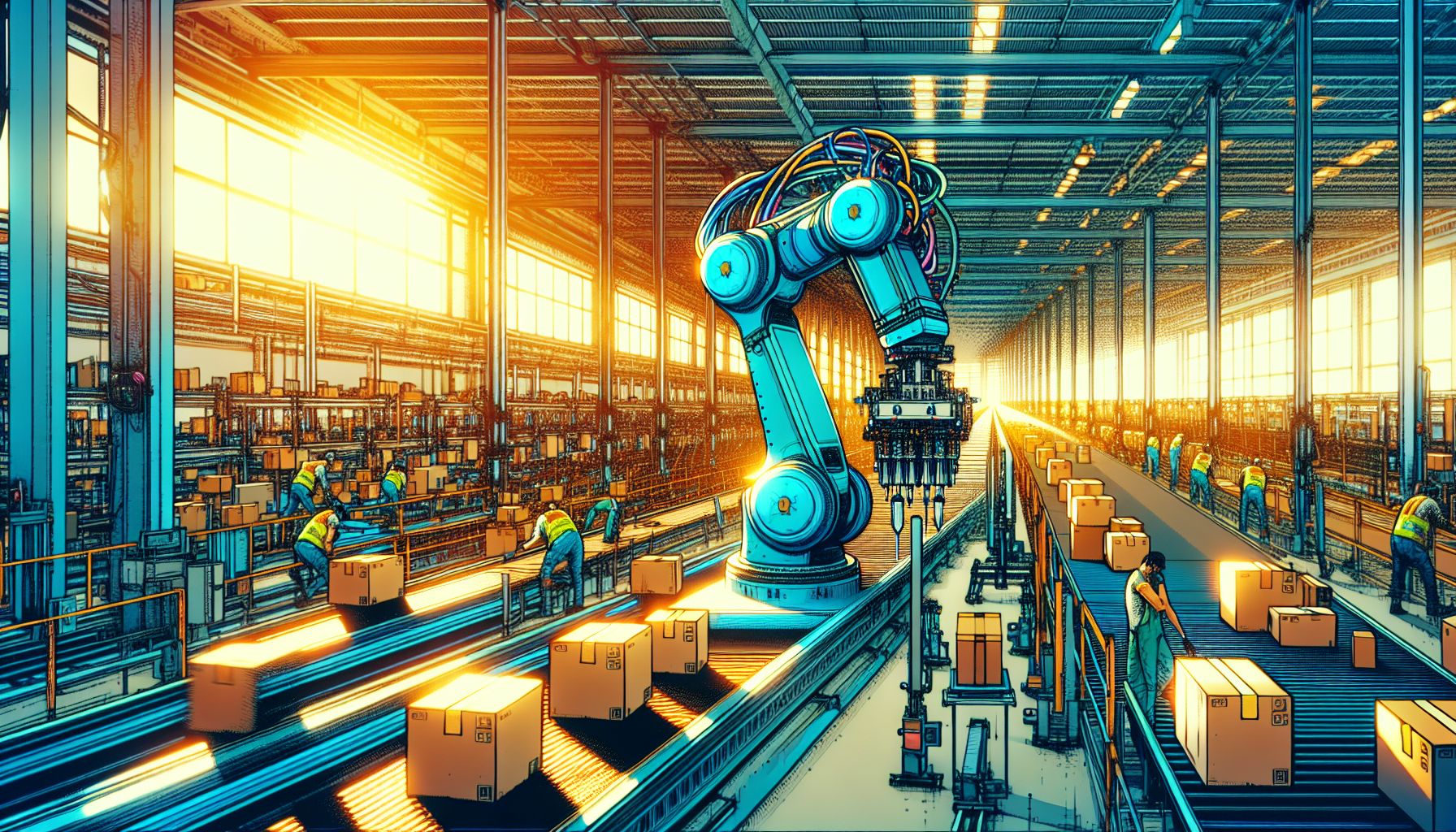

GLS Netherlands introduces ROSI, an AI-powered robotic singulator, at its Utrecht sorting center. This groundbreaking implementation marks the first robotic solution within the GLS Group, processing 1,600 parcels per hour. The pilot project could revolutionize logistics efficiency across GLS’s international network.

The Rise of Robotic Innovation in Utrecht

On October 14, 2024, GLS Netherlands, in collaboration with AWL, launched a pioneering robotic solution at its Utrecht sorting center. Named ROSI, this Robotic Singulator is designed to enhance the efficiency of parcel processing by singulating mini-parcels on conveyor belts. Utilizing advanced vision technology and artificial intelligence, ROSI identifies and processes parcels weighing up to 5 kilograms at an impressive rate of 1,600 parcels per hour[1][2].

Enhancing Efficiency and Employee Experience

The introduction of ROSI is a strategic move to optimize logistics processes while improving working conditions for employees. By automating repetitive tasks, ROSI allows human workers to focus on more complex duties, thereby diversifying their roles and increasing overall operational efficiency. This innovation is particularly significant given the limited floor space at the Utrecht facility, making it an ideal testing ground for such technology[3][4].

Local Collaboration with Global Implications

The pilot project is a result of close collaboration between GLS Netherlands and AWL, a renowned robotic systems integrator headquartered in Harderwijk. AWL is concurrently testing a new high-tech gripper to further enhance parcel handling capabilities at the Utrecht site. The success of this pilot could significantly influence the GLS Group’s broader innovation strategy, potentially leading to the widespread adoption of robotics across its international distribution network[2][3].

A Vision for the Future

Should ROSI continue to perform effectively, GLS Netherlands envisions expanding this robotic technology throughout its global operations, thereby setting a new standard in logistics efficiency. This move aligns with the broader industry trend where artificial intelligence and robotics are increasingly recognized as transformative forces in logistics, enhancing supply chain operations by boosting productivity and minimizing errors[5][6].