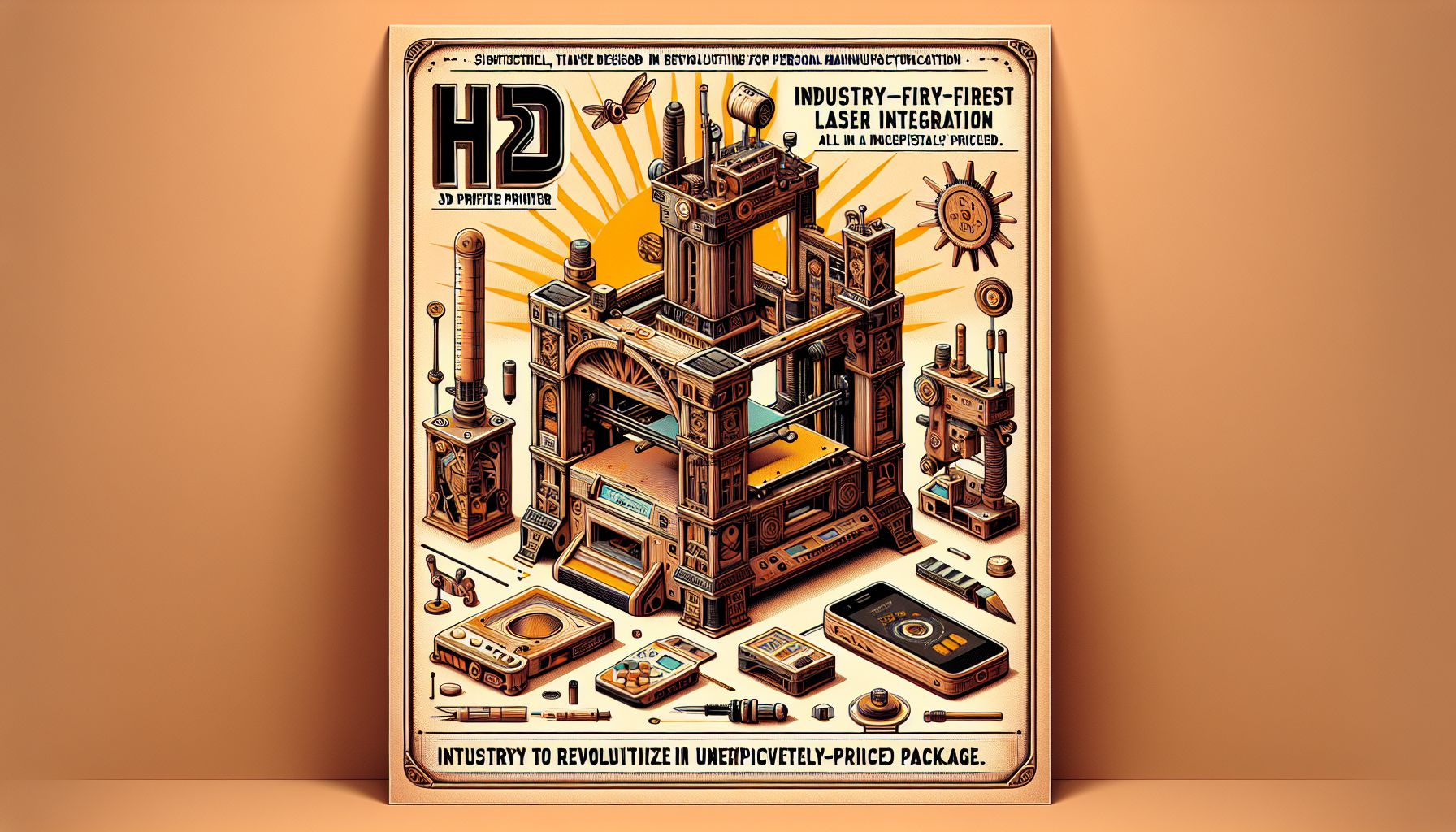

Bambu Lab Unveils Groundbreaking H2D 3D Printer

Amsterdam, Wednesday, 26 March 2025.

The H2D 3D printer by Bambu Lab introduces an industry-first laser integration at an unexpectedly low price, redefining capabilities and accessibility in personal manufacturing.

Revolutionary Integration of Laser Technology

The H2D introduces unprecedented versatility by combining professional-grade 3D printing with laser engraving and cutting capabilities [1]. The system features advanced safety measures, including laser-resistant windows, five flame detectors, and AI camera monitoring, establishing new standards for desktop manufacturing equipment [2]. With positioning accuracy of 0.3mm for laser operations and a Vision-Assisted Encoder System delivering 50µm motion accuracy [3], the H2D represents a significant leap in precision manufacturing capabilities.

Technical Specifications and Performance

The machine boasts impressive specifications with a build volume of 350 x 325 x 320 mm and a maximum toolhead speed of 1000 mm/s [3]. A notable innovation is the DynaSense Servo PMSM Extruder, which provides real-time monitoring of extrusion pressure [3]. The dual-nozzle system can reach temperatures of up to 350°C, while the heated chamber maintains temperatures up to 65°C [3], enabling work with a wide range of materials.

Market Positioning and Pricing Strategy

In a surprising market move, Bambu Lab has positioned the H2D at remarkably competitive price points. The base model will be available in June 2025 at €1,899, while the AMS combo version launches immediately at €2,235 [2]. The laser-equipped variants, available for pre-order from March 25, 2025, are priced at €2,846 for the 10W laser version and approximately €3,546 for the 40W laser model [2][3]. This pricing strategy comes at a time when Bambu Lab has demonstrated significant market growth, with reports showing the company outpacing other desktop 3D printer manufacturers in Q4 2023 [4].

Enhanced Material Management

The H2D introduces two specialized AMS (Automated Material System) variants. The AMS 2 Pro features intelligent ventilation that automatically switches between drying and storage modes, while the AMS HT is specifically engineered for technical filaments with capabilities to dry materials at temperatures up to 85°C [2]. These innovations address crucial material handling challenges, particularly for professional users working with advanced materials.