Breakthrough in Battery Recycling: New Method Extracts 50% of Lithium in 30 Seconds

Eindhoven, Thursday, 1 August 2024.

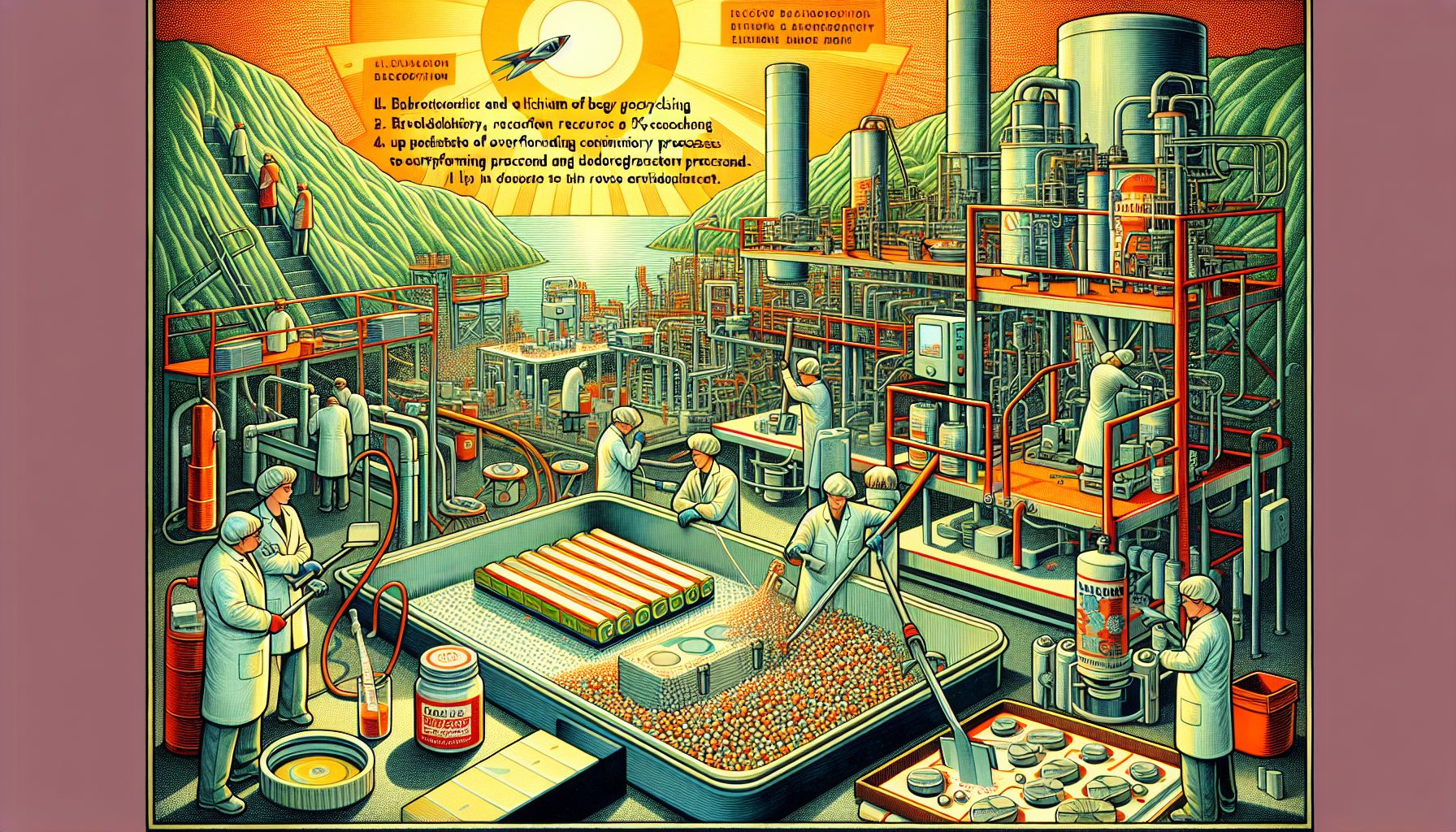

Rice University researchers have developed a revolutionary lithium extraction technique for battery recycling. Using microwave radiation and a biodegradable solvent, the method recovers up to 50% of lithium in just 30 seconds, significantly outperforming conventional processes. This innovation could reduce new lithium mining and its associated environmental impacts.

Traditional Lithium Extraction Methods

Conventional lithium extraction methods are notoriously inefficient, often recovering less than 5% of lithium due to contamination and energy-intensive processes. Traditional techniques such as salt flat brine extraction and open-pit mining not only yield low recovery rates but also have significant environmental and social costs. These methods contribute to soil degradation, water shortages, and loss of biodiversity[1].

The Innovation at Rice University

The research team at Rice University, led by Sohini Bhattacharyya and including Salma Alhashim, introduced a method using microwave radiation and a biodegradable solvent known as a deep eutectic solvent (DES) made of choline chloride and ethylene glycol. This method can extract up to 50% of lithium from spent batteries in just 30 seconds, marking a significant leap from the less than 5% recovery rate of conventional methods[2].

Environmental and Economic Benefits

By enhancing the recovery rate, this novel method could substantially reduce the need for new lithium mining, which is associated with severe environmental impacts including significant water depletion and habitat destruction. The innovation also addresses the rising demand for lithium-ion batteries, driven by the growing market for electric vehicles (EVs), renewable energy storage, and portable electronics. The global market for lithium-ion batteries was valued at over $65 billion in 2023 and is expected to grow by more than 23% in the next eight years[3].

Implications for the Battery Industry

This breakthrough in lithium extraction could revolutionize the battery recycling industry, making it more economically viable and environmentally friendly. The improved efficiency and reduced energy consumption of the Rice University method may attract investment in recycling infrastructure, promoting a circular economy in the battery industry. Additionally, the high-purity lithium recovered using this method could enhance battery production and the clean energy sector[4].

Future Prospects and Industry Impact

The findings, published in the journal Advanced Functional Materials on July 29, 2024, underscore the potential of this new extraction technique to minimize environmental impact while meeting the growing demand for critical metals like lithium. Pulickel Ajayan, the study team lead, emphasized that the method not only enhances the recovery rate but also minimizes environmental impact, addressing concerns over the availability of critical metals and the environmental footprint of lithium extraction[2].