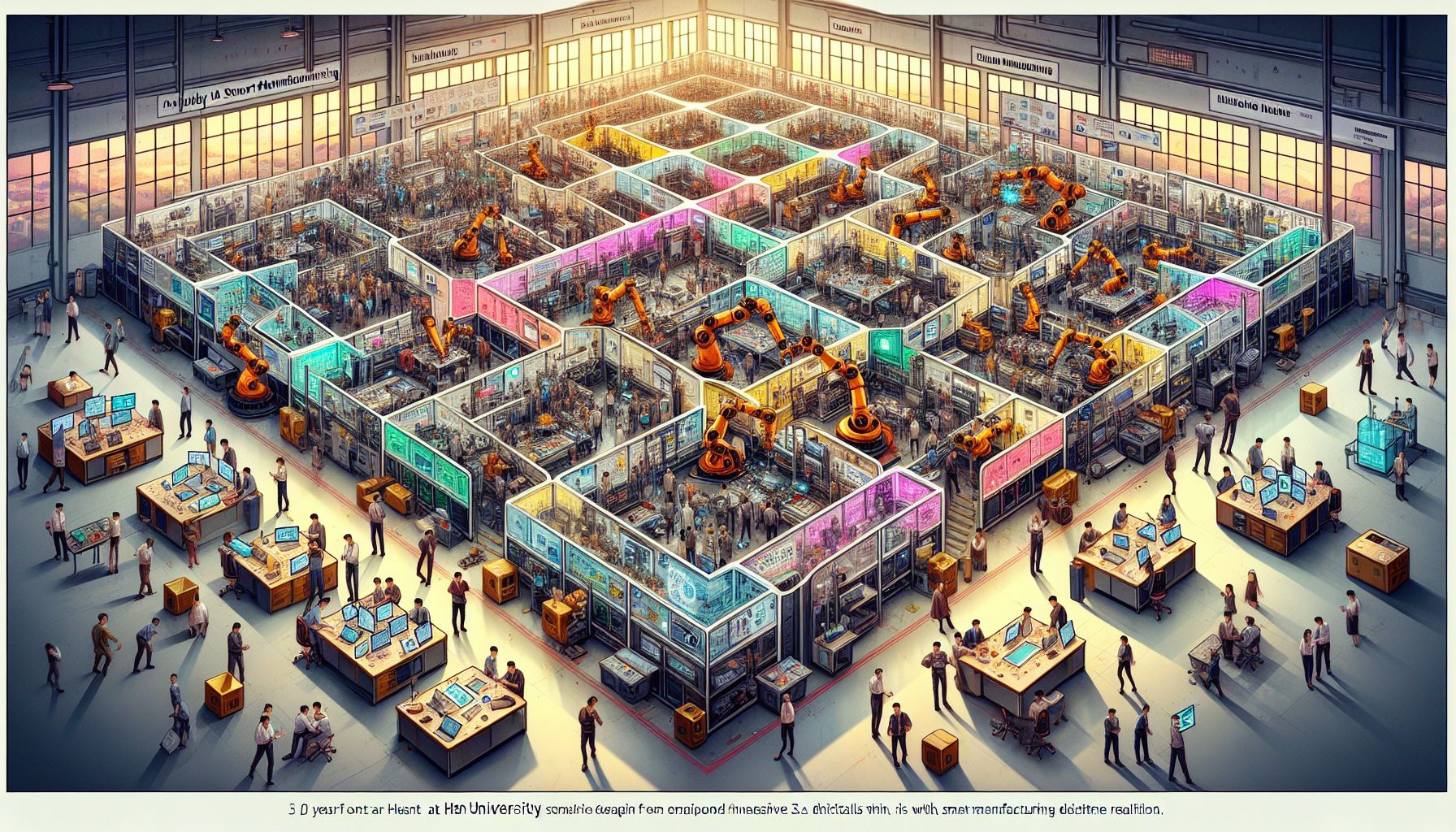

HAN's U-Shaped Assembly Cell: Two Years of Smart Manufacturing Innovation

Arnhem, Thursday, 29 August 2024.

HAN University’s U-Shaped Assembly Cell (USAC) marks two years of advancing smart production for SMEs. This innovative platform integrates digital twins, robotics, and augmented reality, demonstrating the potential of Industry 4.0 technologies in discrete manufacturing. With 36 students contributing to real-world projects, USAC is paving the way for the future of adaptive, cyber-physical production systems.

A Hub for Technological Advancements

Located at HAN University of Applied Sciences, the U-Shaped Assembly Cell (USAC) has become a cornerstone for technological innovation in the Netherlands. Over the past two years, it has evolved from a simple learning environment into a sophisticated hub that champions the integration of cutting-edge technologies like digital twins, robotics, and augmented reality. These advancements are not just theoretical but have been practically implemented to optimize production processes, making tangible contributions to local small and medium-sized enterprises (SMEs).

Student Contributions and Real-World Applications

The involvement of 36 students in the last year alone highlights the program’s commitment to applied learning and research. These students have worked on various projects that have significantly improved efficiency, flexibility, and product quality in discrete manufacturing. For instance, one major project involved the implementation of an operations digital twin, which collected real-time data for production simulation and optimization. This project not only provided valuable insights but also demonstrated the practical applicability of Industry 4.0 technologies in a real-world setting.

Expanding Technological Horizons

The USAC has also been a testing ground for expanding the use of robotics within manufacturing processes. Technologies such as delta pickers have been integrated, and operators are now supported by augmented reality and smart beamers to enhance product quality. These innovations are not just about automating tasks but are also focused on creating a collaborative environment where human operators and robots can work together efficiently.

Future Directions and Industry Collaboration

Looking ahead, the focus is on developing a fully integrated cyber-physical production system that can dynamically adapt to new technologies without disrupting ongoing production. This system aims to be flexible and scalable, allowing for the seamless addition of new subsystems. Collaboration with local SMEs is crucial for refining these technologies to meet industry needs and challenges. This partnership ensures that the research and innovations developed at USAC are directly applicable and beneficial to the manufacturing industry.

Emphasis on Applied Research

The future of USAC is bright, with a strong emphasis on applied research to experiment with the latest technologies. This approach not only benefits the students and researchers involved but also provides local SMEs with innovative solutions that can be directly implemented in their production processes. The goal is to create a smart production environment that is not only efficient but also adaptable to the ever-changing landscape of the manufacturing industry.